Your Credit Estimate

Your Credit Estimate

Your Credit

Your Credit

Your zip code helps us provide you with the most accurate vehicle pricing and vehicle availability.

We estimate your credit score to give you an idea of your monthly payments. To get an accurate payment amount, complete our credit application by clicking the Start Credit Application button below.

start credit application

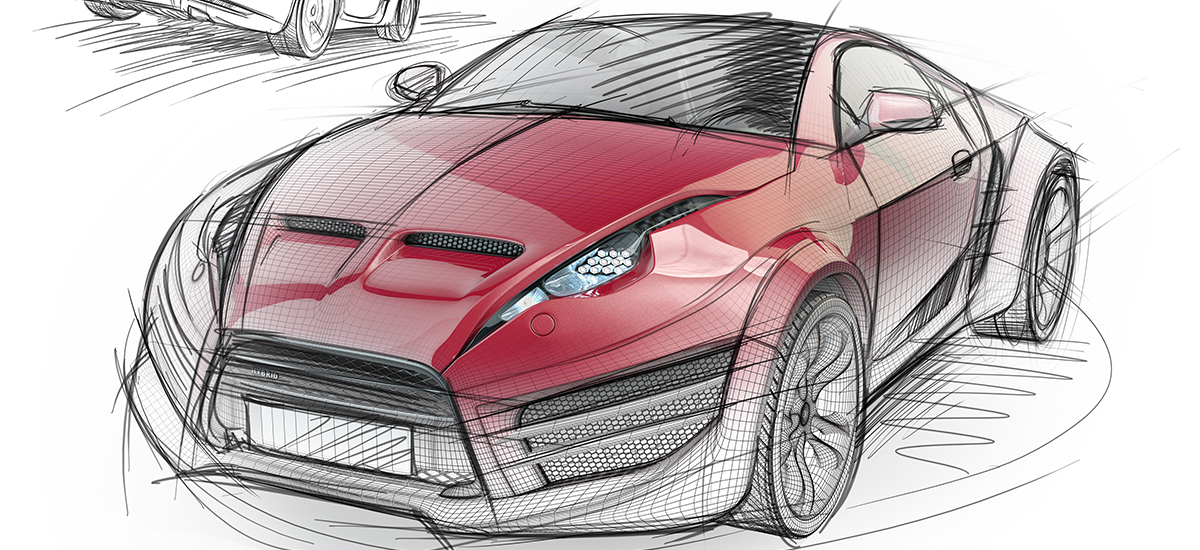

A lot goes into the building of automobiles, a lot more than one may think. Automakers don’t just make a prototype to show off at the next auto show and build it based on audience reaction. Before prototypes are even constructed, it starts with a concept. To this day, automotive designers still sketch a draft of a vehicle, be it ink or digital, when starting the automotive production process.

An Idea

It all starts with an idea, the starting point for every new vehicle. It starts with a sketch or a design that not only captures the look of an auto brand but also creates a package for the consumer. What style is this idea based on? What technology is offered, how would it compare with competitors in the market? A lot of research takes place here as well - collecting data on vehicle segments, the market, technological advancements, deadlines, costs and pricing, etc. When all of this is combined and analyzed, an automaker decides if producing the new product is feasible.

Digital Production

If a new vehicle is given the green light, then it’s time to give a concept a little more life. This is most commonly done with 3D modeling, computer-aided design systems, or any other software that can aid in drafting a more detailed version of the concept. These detailed designs are then used as the template for the production of prototypes and future models. The cost plays a bigger role here, signing off on or rejecting ideas that don’t fit in the budget for a new product, and this phase can take awhile before engineers create an optimal solution that fits both the technical and economical goals of the company, consumer, and vehicle.

Simulations

Just like crash testing, before a prototype is even constructed, the digital version is run through various scenarios virtually to test it out. This allows automakers to optimize every component and the system as a whole to tackle problems or issues with vehicle design, safety, performance, etc. Then comes the testing phase.

Stress Tests

Prototypes are never the final product, but they can easily pass off as one. During the development of a new vehicle, every piece is stress tested under realistic conditions. Be it the electronics, the engine, or the entire vehicle, they are tested for durability and the ability to withstand tough conditions. These prototypes then go through a series of other steps.

Design Validation - A prototype is normally built with cheap alternatives or cost-effective resources that can be used to create a simple physical object for a visual of the concept and demonstration. The design may even be shown to stakeholders to get investments and funding for the vehicle.

Pre-Development - Once the design is validated and funded, a more refined version of the prototype is constructed. It is a chance for automakers to consider design alternatives and address issues that arise. To do this, older cars may be stripped down, or even just the platform of a vehicle may be used to develop this version of the prototype and analyze how well it fits into the current market.

Production - Now comes the part where a prototype can be produced. The ideal methods for creating the automotive product - be it certain resources, construction techniques, or production challenges - can be spotted early on to determine the most cost effective process, such as sending it off to another assembly plant better suited to manufacture that vehicle.

Testing - As more and more data is collected for the prototype, it goes through various tests. Some prototype models will be sent to customers who can provide valuable feedback, spot issues, and comment on the vehicle overall from its desirability to difficulty of use for everyday activities. The prototype is also put through safety tests, and really this is when the majority of stress testing takes place.

Validation - The final step before production, prototypes are built to stand-in for the final product so that finishing touches may be applied prior to production, made with the same machinery and in the same plant, so that a product may be finalized. These prototypes may even be brought to auto shows to give a finished sense of the product, when really production has yet to start.

It’s Alive!

After all of this, the product development process starts coming to a close. Was what once a concept has been funded, tested, and finalized. The vehicle is constructed and produced, marketing starts up, the vehicle is advertised before it’s even on the streets.

Launch

The new vehicle hits showrooms and dealership lots, and is available for purchase. The production process ends.

Who knew so much went into creating an automobile? As a consumer, we may not really consider all the work that goes into making a vehicle, and it’s nice to know though that so much work goes into making the products we take for granted today. What are some of your favorite vehicles? You can find many choices in our inventory. Just start up a search on NowCar.